Integrated Quality Process for Zero Defects

An outstanding commitment to excellence is what makes Datwyler a partner you can trust. Through a proactive systematic quality process, Datwyler maintains a steadfast focus on zero defects, providing customers with outstanding products that exceed expectations.

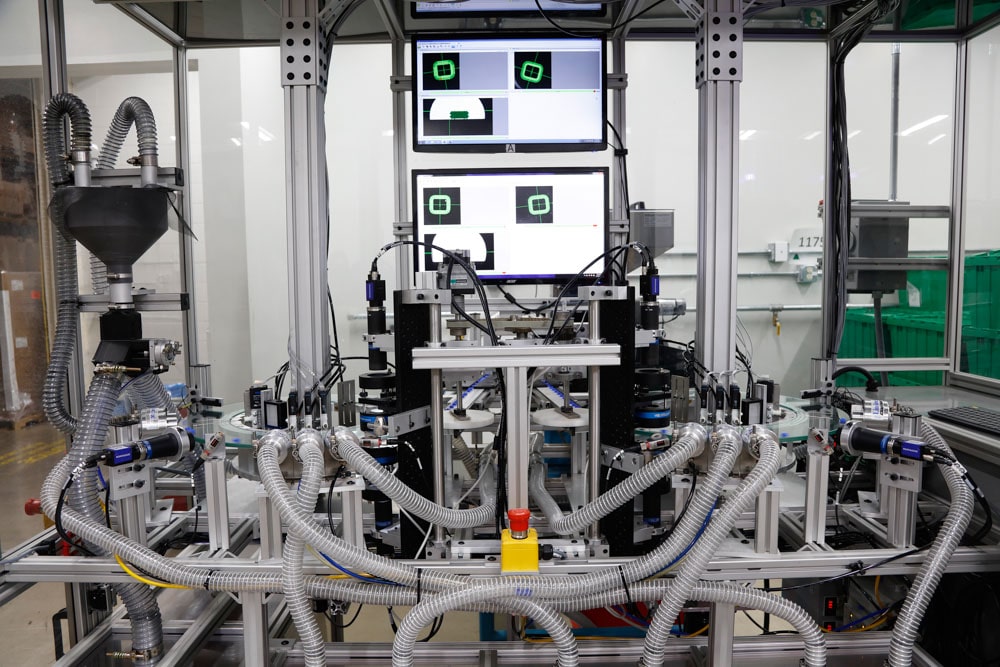

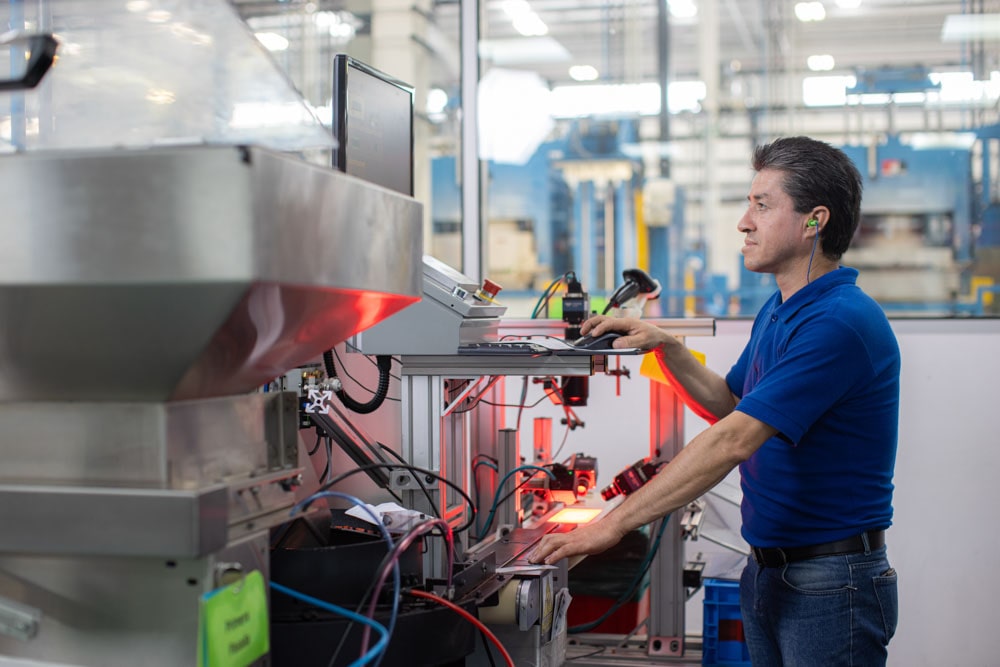

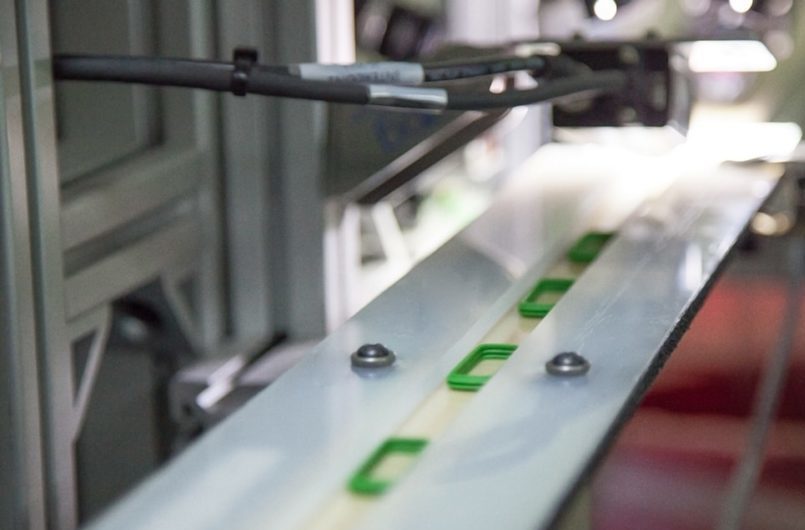

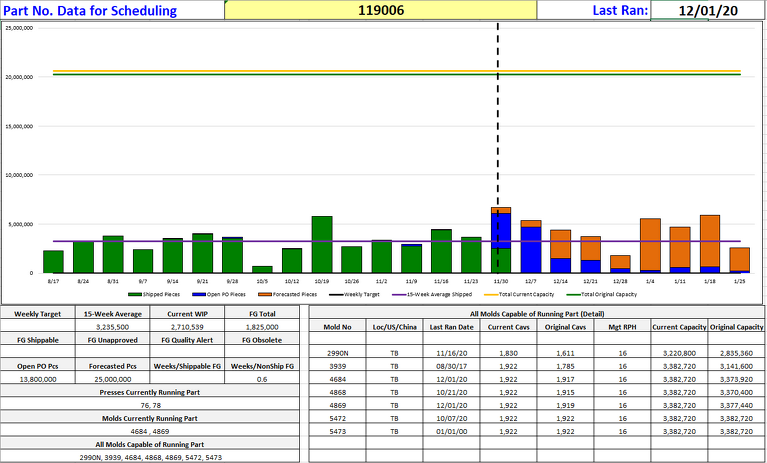

Datwyler employs Poka-yoke systems and continuous improvement practices throughout production to ensure best-in-class quality across the globe:

- IATF 16949 certified quality management systems

- Environmental management system meeting ISO 14001 requirements

- Product development methodology executed in accordance with AIAG APQP guidelines

- Streamlined project management system providing full visibility and tracking of ongoing operations

- Well-established LEAN Manufacturing program

- Layered Process Audit System (LPA) to monitor manufacturing processes to ensure effectiveness

- A sophisticated lot traceability system to control and record every step of the process